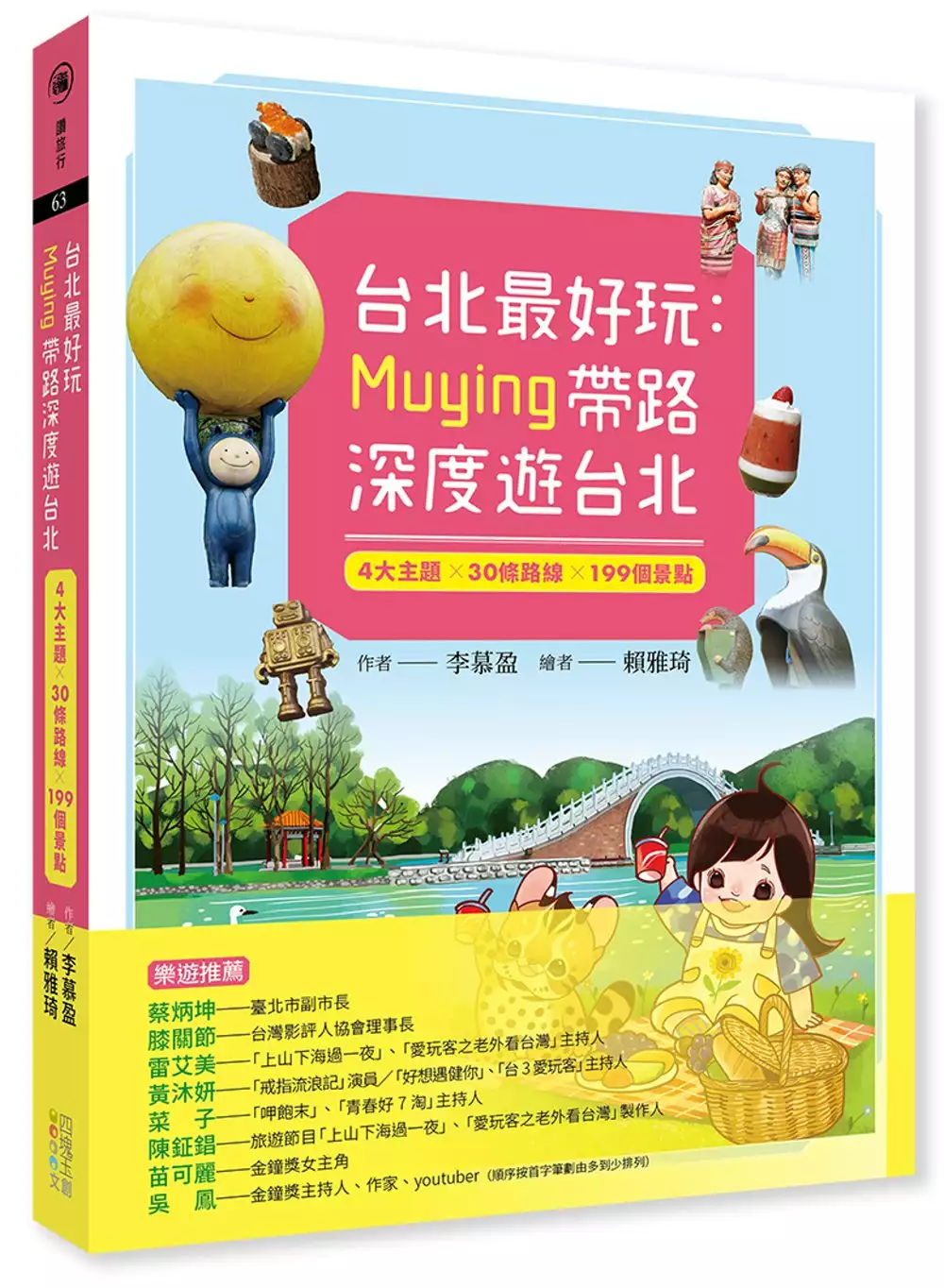

Saffron 46 ig的問題,我們搜遍了碩博士論文和台灣出版的書籍,推薦李慕盈寫的 台北最好玩:Muying帶路深度遊台北:4大主題╳30條路線╳199個景點 可以從中找到所需的評價。

另外網站微風南山頂級印度菜– SAFFRON 46 番紅花46 - Toby is Here也說明:今天又到了信義區來欣賞高空景觀餐廳,繼之前在Morton吃了以後,又一次造訪了高空餐廳。SAFFRON番紅花46是印度菜餐廳,說到印度菜,那肯定是重口味的。

長庚大學 電子工程學系 陳始明所指導 Udit Narula的 超大積體電路中石墨烯化銅互聯線的製程方法研究 (2017),提出Saffron 46 ig關鍵因素是什麼,來自於ULSI互連、石墨烯合成方法、Graphenated銅、電遷移。

而第二篇論文國立中山大學 生物科學系研究所 趙大衛所指導 陳冠豪的 薑黃素對胰液所誘導肺損傷之保護效用 (2014),提出因為有 肺損傷、缺血再灌流、支氣管灌洗液、全套肺功能相關生理試驗、肺組織灌洗液中蛋白質、薑黃素、氮化壓力的重點而找出了 Saffron 46 ig的解答。

最後網站

台北最好玩:Muying帶路深度遊台北:4大主題╳30條路線╳199個景點

為了解決Saffron 46 ig 的問題,作者李慕盈 這樣論述:

踏訪台北11+1區, 感受台北來自四面八方的活力, 從老台北的復古風情,到現代台北的新潮繁華, 帶你體會新舊台北交織出的獨特韻致。 台北,你想怎麼玩? 是鑽進飛機巷近距離觀看飛機起降、 沿著深奧鐵道騎腳踏車健行、 走入寶藏巖聚落體驗藝術與人文的共生、 在西門紅樓喝喝咖啡、跳跳舞、 穿梭於大安巷弄之中嘗遍傳統美食、 或是到訪紀州庵文學森林,聽一場文學講座呢? 從這一區到那一區,無論文青派、潮流派或旅遊派, 都能在此找到專屬你的台北方程式! 本書特色 ◆4大主題╳199個景點,任你搭配任你玩! 打開台北人的口袋名單,踏訪私藏的絕美風景

、享用最道地的排隊美食、能炒熱氣氛的酒吧和俱樂部當然也不容錯過……白天到黑夜,台北的熱鬧永遠不停歇! ◆30條一日遊路線╳3大主題,想去哪裡都可以! 無論是體驗台北日常的漫步之旅、充滿粉紅泡泡的情侶出遊,甚至是上山下海的冒險挑戰,跟著路線規劃走,玩得盡興又安心! ◆大眾運輸搭配導航QRcode,不開車也能台北玩透透! 書中每個景點都配有行程QRcode,讓你用最少的時間,最快到達目的地,手機一掃,立即出發,絕對不迷路 ! 樂遊推薦 蔡炳坤──臺北市副市長 膝關節──台灣影評人協會理事長 雷艾美──「上山下海過一夜」、「愛玩客之老外看台灣」主持人 黃

沐妍──「戒指流浪記」演員/「好想遇健你」、「台3愛玩客」主持人 菜子──「呷飽未」、「青春好7淘」主持人 陳鉦錩──旅遊節目「上山下海過一夜」、「愛玩客之老外看台灣」製作人 苗可麗──金鐘獎女主角 吳鳳──金鐘獎主持人、作家、youtuber (順序按首字筆劃由多到少排列) 「作者才華橫溢,除了妙筆生花的文筆,還運用四大主題將台北介紹透徹,用年輕人的角度走讀台北,是本隨時會想帶在身上的旅遊書!」──蔡炳坤/臺北市副市長 「這年頭願意為自己專注熱情,一步一腳印地踏遍以上巡點足跡,非常不容易。從採訪整理景點中,給當代國旅踏青者一份屬於新生代的集錦耕耘,是很不容易的

工程。」──膝關節/台灣影評人協會理事長 「感受人情溫度,玩出旅行深度,跟著慕盈一起走進台北大街小巷。」──黃沐妍/「戒指流浪記」演員、「好想遇健你」&「台3愛玩客」主持人 「慕盈是個很懂吃喝玩樂的作家,透過生動的描述,能讓讀者心中產生一幅不同風貌的台北地圖!」──菜子/「呷飽未」、「青春好7淘」主持人 「知名旅遊節目出身的作家,哪裡好吃,哪裡好玩,絕對嚴選再嚴選,是行家級的獨特介紹。」──陳鉦錩/旅遊節目「上山下海過一夜」、「愛玩客之老外看台灣」製作人 (順序按首字筆劃由多到少排列)

Saffron 46 ig進入發燒排行的影片

Saffron 46 這間我已經去3次了!真的很喜歡!景觀超美!如果你喜歡印度料理、喜歡香料,那你一定要去吃看看!

好開心可以跟好友一起去漂亮的餐廳過平安夜~

大家聖誕節快樂!

IG: https://instagram.com/jennaaawang?igshid=1u5fakezo0m5s

RYYZN - It's Not Christmas Time (Without You) (feat. Kimmy Baggins)

Free Download: bit.ly/3hk2lmS

YouTube: www.youtube.com/watch?v=qtTZnylFI1E

Lyrics: genius.com/Ryyzn-its-not-chris…-without-you-lyrics

超大積體電路中石墨烯化銅互聯線的製程方法研究

為了解決Saffron 46 ig 的問題,作者Udit Narula 這樣論述:

Recommendation Letter from the Thesis Advisor……………………………………Thesis/Dissertation Oral Defense Committee Certification……………………Acknowledgments……………………………………………………………………… iiiChinese Abstract……………………………………………………………………… ivEnglish Abstract…………………………………………………………………………vTable of Contents…………………………………………………………

……………viList of Figures…………………………………………………………………………ixList of Tables………………………………………………………………………… xvChapter 1: Introduction………………………………………………………………11.1 Brief History of ULSI/VLSI Interconnects’ Electromigration………11.2 Limitations of Copper Interconnects………………………………………21.3 Alternative to Copper Intercon

nects………………………………………31.4 Motivation of Dissertation …………………………………………………5Chapter 2: Prospects of Graphene……………………………………………………92.1 Properties and Applications of Graphene……………………………………92.2 Graphene Synthesis Methods……………………………………………………102.3 Need for a New Growth Method…………………………………………………102.4 Summary

of Prospects of Graphene……………………………………………12Chapter 3: Development of a New Method for Graphenated Copper……………133.1 Phase I: Sample Preparation using PVD method……………………………133.2 Phase I: Post-PVD Annealing …………………………………………………153.3 Phase I: Characterization ……………………………………………………163.4 Phase II: Sample Pr

eparation using PVD method………………………… 183.5 Phase II: Post-PVD Annealing & Characterization……………………… 193.6 Summary of PVD Based Growth Method ……………………………………… 23Chapter 4: Mechanism of PVD Based Growth Method………………………………244.1 Effect of a-C layer thickness on Graphene growth………………………244.2 Effect of ann

ealing time on Graphene growth…………………………… 264.3 Effect of annealing temperature on Graphene growth……………………294.4 Stress Analysis using Finite Element Modelling (FEM)…………………304.5 Explanation of Experimental Results using FEM………………………… 344.6 Summary of Growth Mechanism………………………………………………… 45Chapter 5: A

pplication of Design of Experiments (DoE)………………………465.1 An Introduction to DoE and its Need in Material Science……………465.1.1 An Introduction to DoE………………………………………………465.1.2 Need for DoE in Material Science…………………………………485.2 OFAT vs 2k Factorial Experiment Design………………………………… 495.2.1 One-Factor-at-a-T

ime Experiments…………………………………495.2.2 2k Factorial Design………………………………………………… 515.3 Qualitative DoE Analysis…………………………………………………… 515.4 Quantitative DoE Analysis……………………………………………………575.5 Filtered Quantitative Analysis…………………………………………… 635.6 Summary of Graphene Growth using DoE…………………………………… 66Chapter 6:

Prospects of Graphenated Copper……………………………………686.1 Electrical and Thermal Characteristics………………………………… 686.1.1 Thermal Properties’ Measurement………………………………… 686.1.2 Electrical Resistivity Measurement……………………………… 716.2 Atomic Level Finite Element Modelling…………………………………… 736.3 Summary of Graphenated C

opper as ‘Game-Changer’…………………… 78Chapter 7: Electrochemical Route for Copper on Graphenated Copper………797.1 Fundamental Principle………………………………………………………… 807.2 Experimental Overview………………………………………………………… 817.2.1 Materials…………………………………………………………………817.2.2 Methods……………………………………………………………………817.3 Copper on

Graphenated Copper…………………………………………………827.3.1 Raman Characteristics…………………………………………………827.3.2 SEM/EDS Analysis……………………………………………………… 837.3.3 Thickness Measurement…………………………………………………867.3.4 XRD Analysis…………………………………………………………… 877.4 Proposed Mechanism of Electroless Cu Deposition using Graphene……887.5

Summary of Copper on Graphenated Copper by Electrochemical Means…92Chapter 8: Conclusion and Future work……………………………………………948.1 Conclusion…………………………………………………………………………948.2 Contribution of the Dissertation……………………………………………958.3 Suggestions for Future Work………………………………………………… 96Bibliography or Reference

s………………………………………………………… 98List of Publications…………………………………………………………………114Journals…………………………………………………………………………………114Conference………………………………………………………………………………115Patent……………………………………………………………………………………117List of FiguresFigure 1.SEM image of a failed sample. [17]……………………………………3Figure 2.Typical package le

vel EM resistance trace.[18]……………………3Figure 3.a) Device under test (DUT) is a 100-μm Graphene wire in contact with Ti/Au electrodes, tested at 30 MA/cm2 at 523 K. b) Interconnect lifetime distribution at 523 K for different wire lengths and stress current densities. Each of the lines in the figure s

hows the lifetime of approximately ten wires, each tested individually.[25]………………………5Figure 4.Intercalation Doped Multilayer-Graphene-Nanoribbons.[26]……… 6Figure 5.Micro-scale aerosol-jet printing of graphene interconnects.[27]6Figure 6.EM performance comparison for Copper.[28]……………………………7Figure 7.Q

uality vs Cost map for Graphene synthesis methods. [51]………11Figure 8.Structure configurations of the samples for Phase I experimentation; a) sample S1 with 60 nm a-C layer underneath 800 nm Cu thin film, b) sample S2 with 60 nm a-C layer atop 800 nm Cu thin film, c) sample S3 with 800 nm Cu thin fil

m sandwiched between two 60 nm a-C layers and d) sample S4 with 60 nm a-C layer sandwiched between two 800 nm Cu thin films.[55]…………………………………………………………………14Figure 9.Sample S1, S1.1 and S1.2 preparation process using PVD…………14Figure 10.Sample S2 preparation process using PVD……………………………15Figure 11.Samp

le S3 and S4 preparation process using PVD………………… 15Figure 12.Chamber for Post PVD annealing.………………………………………16Figure 13.Recipe for Post PVD annealing…………………………………………16Figure 14.Raman Spectrum of annealed sample S1.[55]…………………………17Figure 15.Raman Spectrum of annealed samples S2, S3 and S4.[55]…………18F

igure 16.XRD analysis on deposited Cu surface shows presence of a high intensity {111} Cu peak in XRD analysis result……………………………… 19Figure 17.Raman Signatures for samples S1.1……………………………………20Figure 18.Raman Signatures for samples S1.2……………………………………20Figure 19.SIMS data for annealed samples S1, S1.1

and S1.2. [55]……… 22Figure 20.SIMS data for sample S1.2 before annealing, showing the presence of a-C layer beneath Cu film……………………………………………22Figure 21.a) Structure design for samples S1, S1.1 and S1.2 having 60 nm, 36 nm and 12 nm a-C layer sandwiched between 800 nm Cu and Si/SiO2(300 nm) substrate

, b) Schematic for annealing process, c) Raman Spectrum of annealed sample S1, d) Raman Spectrum of annealed sample S1.1, e) Raman Spectrum of annealed sample S1.2.[31]……………………………………………25Figure 22.I2D/IG and ID/IG vs anneal time measured by Raman Spectroscopy. Red lines are for the I2D/IG peak ratio

with the scale on the left y-axis, and blue lines are for the ID/IG peak ratio with the scale on the right y-axis. Dotted lines indicates the uncertainty of the trend as mentioned in the text.[31]…………………………………………………………26Figure 23.Raman Mapping of 10 µm × 10 µm area recorded in steps of 1 µm in all

directions for sample S1.1 annealed at 1020oC for a), b) 20 minutes and c), d) 30 minutes.[31]………………………………………………27Figure 24.Raman Mapping of 10 µm × 10 µm area recorded in steps of 1 µm in all directions for sample S1.2 annealed at 1020oC for a), b) 5 minutes and c), d) 8 minutes.[31]………………………………………

………………… 27Figure 25.Plots of Raman spectrum for sample S1.1 and S1.2 annealed at 920oC and 820oC for 50 mins.[31]…………………………………………………29Figure 26.ANSYS® simulation results of a)-c) Maximum Principal Stress distributions in the three samples at 1020oC, zoning into the maximum stress areas, d)-e) Von-Mi

ses stress in Cu at the corner of each sample, showing the delamination at the a-C/substrate and Cu/a-C interfaces in these sample. [56]……………………………………………………………………32Figure 27.ANSYS® simulation of thermal strain in Graphene on Cu at 1020oC.[31]…………………………………………………………………………… 33Figure 28.Governing reacti

ons [56], [80] for Graphene growth forming the basis for proposed mechanism of Graphene synthesis on Copper film; Here C represents Carbon atom, Gr represents Graphene, CH*/C* represent Hydrogen bonded-Carbon radical/Carbon radical, H* represent Hydrogen radical and ∆H represents heat. [31]………………………

……………………………………35Figure 29.Evolution of stress with decrease in a-C layer thickness. [31]……………………………………………………………………………………………39Figure 30.ANSYS® simulation results for samples S1, S1.1 and S1.2 showing total deformation in the samples which migrates from the corners to the center with the decrease in a

-C layer thickness. [31]…………………… 40Figure 31.ANSYS® simulation results a)-c) maximum von-Mises stress at a-C/Cu interface for sample S1 with respect to different annealing temperatures, d) plot of total deformation in samples S1, S1.1 and S1.2 vs different annealing temperatures. [31]……………………………………

42Figure 32.Relation between thermo-mechanical strain and Raman frequencies of G (ωG) and 2D (ω2D) modes; The data points for samples S1.1 and S1.2 (represented by red-dotted linearly fitted line) are lying parallel to the unstrained graphene line [87], [88] (purple dashed line) and indicate compres

sive strain. [31]……………………………………………………………44Figure 33.Brief History of concepts introduced for DoE in industrial applications……………………………………………………………………………48Figure 34.Illustration of an OFAT experiment in a photolithography experiment. [102]…………………………………………………………………… 50Figure 35.Main effect plots for A

ttribute-Response DoE Analysis of R1…54Figure 36.Interaction plots for Attribute-Response DoE Analysis of R1…54Figure 37.Optimum parameters for maximized response R1…………………… 55Figure 38.Raman Characteristics for experimental run with optimized parameters……………………………………………………………………………… 56Figure 39.Mai

n effect plots for Quantitative DoE Analysis of R2 (left) and R3 (right).[108]………………………………………………………………… 58Figure 40.Interaction plots for Quantitative DoE Analysis of R2 (left) and R3 (right).[108]………………………………………………………………… 58Figure 41.Contour plot analysis for response R2.[56]……………………… 61Figure 42.C

ontour plot analysis for response R3.[56]……………………… 61Figure 43.Plots of ID/IG and I2D/IG peak intensity ratios vs annealing time, for samples with thin a-C layer annealed at 1020oC.[56]……………63Figure 44.Optimum recipe for minimum ID/IG peak and maximum I2D/IG peak intensity ratios……………………………………………………

………………… 64Figure 45.Summary of application of DoE in Graphene Synthesis Process…66Figure 46.Thermal scanner images of Graphenated Cu and Cu thin film on Si/SiO2 substrate………………………………………………………………………69Figure 47.Raman Characteristics of Post-PVD Annealed sample for different annealing durations of (a)

20 minutes and (b) 50 minutes. [submitted for publication]……………………………………………………………………………70Figure 48.Thermal scanner results of Post-PVD Annealed sample for different annealing durations of (a) 20 minutes and (b) 50 minutes. [submitted for publication]……………………………………………………… 70Figure 49.Simple circuit m

odel for Graphenated Copper.……………………73Figure 50.Atomic level Finite Element Simulation steps……………………74Figure 51.Model of the Test structure redrawn using work by Tan et al. [118]………………………………………………………………………………… …74Figure 52.Atomic Flux Divergence calculation for FEM simulation of M1-M2 EM Test Struct

ure. [submitted for publication]………………………………76Figure 53.Resistance change for FEM simulation of M1-M2 EM Test Structure. [submitted for publication]…………………………………………76Figure 54.Average of Total-Average AFD for FEM simulation of M1-M2 EM Test Structure with and without Graphene………………………………………77Figure

55.Graphene sandwiched within copper interconnection.[submitted for publication]………………………………………………………………………79Figure 56.Graphenated Cu dipped in Copper Sulphate (CuSO4) solution for 3, 6, 9 and 12 hours. [submitted for publication]………………………… 81Figure 57.Interaction of electrolyte with Graphene sittin

g on Cu foil. (a) Optical image of untreated Mono-layer Graphene on Cu foil, (b) Optical image of electrolyte-treated Mono-layer Graphene on Cu foil, (c) Raman spectra of (a) and (b) using Horiba LabRAM HR Evolution Raman Spectrometer. [submitted for publication]…………………………………… 82Figure 58.SEM image

of (a) Fresh Graphenated Cu sample in SEI mode, (b) Sample treated with electrolyte for 3 hours in SEI mode (c) Sample treated with electrolyte for 12 hours in SEI mode. (d), (e) and (f) are the same images as (a), (b) and (c) respectively, but in TOPO mode. (Accelerating Voltage= 5 kV, Emission Cur

rent= 10 µA; Working Distance= 5.7-6.1 mm, Magnification= 2500x); Measurement taken using JEOL-JSM SEM with OXFORD instruments EDS. The grown islands are marked by white arrows. [submitted for publication]………………………………………………83Figure 59.EDS Mapping of Sample treated with electrolyte for 3 hours for C,

O and Cu (Accelerating Voltage= 15 kV, Magnification= 2500x, Counts= 3.5 million); Measurement taken using JEOL-JSM SEM with OXFORD instruments EDS. [submitted for publication]………………………………… 85Figure 60.EDS Mapping of Sample treated with electrolyte for 12 hours for C, O and Cu (Accelerating Voltage

= 15 kV, Magnification= 2500x, Counts= 3.5 million); Measurement taken using JEOL-JSM SEM with OXFORD instruments EDS. [submitted for publication]………………………………… 85Figure 61.Thickness of deposited Cu domains (measured using a Keyence confocal Optical Microscope VHX-5000) vs time of sample dipping/trea

tment with the electrolyte, with error bars indicated by the blue vertical lines. [submitted for publication]……………………………………………… 86Figure 62.XRD pattern for Fresh Graphenated Cu sample and Sample treated with electrolyte for 12 hours from PANalytical Empyrean XRD System. (#) Pure Copper peak of {200}

and {400} orientation, (*) Cubic Cu2O peaks of {111} and {222} orientation and (∆) Pure Copper peak of {111} orientation are observed. [submitted for publication]………………………………………87Figure 63.Cause of Polarization effect due to difference in work function of Copper (Cu) and Graphene (Gr) depicted by (

a) Density of States (DOS) diagram before contact (drawn using understandings from work done by Nagashio et al.[140]) (b) Energy band diagram for Graphenated Copper. Here dCu-Gr (3.26 Å [136]) represents equilibrium separation of the Graphene sheet from Cu metal surface, WFCu (5.22 eV [141]), WFGr (

4.40 eV [141]) and WF (4.367 eV [141]) are the work functions of Copper, Graphene and Graphene covered Copper (Graphenated Cu) respectively, ΔEf (WF - WFGr) is defined as the energy (per carbon atom) required to separate the graphene sheet from the Cu surface, ΔV is the potential change generated by

the metal-graphene interaction and Ef is the Fermi energy (drawn using the understandings from the work done by Giovannetti et al.[ 141]). [submitted for publication]…………………………………………………………89Figure 64.Charge transfer for Electroless Copper deposition using Graphenated Cu as a reducing agent. Here EF

(Gr-Cu) (~4.1 eV), EF(Cu2+/Cu) (5.19 eV [149]) and EF are the energy levels of Graphenated Copper, Cu Redox reaction and Electrolyte-treated Graphenated Cu respectively. [submitted for publication]…………………………………………………………90Figure 65.Trend of ΔEf with respect to dM-Gr for metals such as Pt, Al, Au, Ag,

Cu [141], [132] and Ni, Co, Ti [140]. [submitted for publication]…………………………………………………………………………………………… 91List of TablesTable 1:Cu Replacement suggested by ITRS [11]…………………………………4Table 2:Comparison of plots in Figure 3 and Figure 6……………………… 7Table 3:Raman Characteristics for annealed samples at 1020oC

for 50 mins [55] ………………………………………………………………………………………21Table 4:Thermo-mechanical properties for stress analysis using FEM…… 32Table 5:DoE Factors for Qualitative and Qualitative Analysis [108][56].52Table 6:Qualitative and Qualitative Full Factorial DoE Analysis [108][56] ……………………………………………………………………………

……………… 53Table 7:ANOVA statistics for Response R2 [56] ……………………………… 59Table 8:ANOVA statistics for Response R3 [56]…………………………………60Table 9:Map of Choice of Levels and Quality & Number of Graphene Layers [56]……………………………………………………………………………………… 62Table 10:Filtered DoE Factors [108] …………………………………………… 65Ta

ble 11:Output Responses for Filtered DoE Analysis [108] ……………… 65Table 12:Four Point Probe measurement for the experimental sample [submitted for publication] ……………………………………………………… 71Table 13:Feature sizes of the Test Structure used in FEM [118]………… 75Table 14:Model Parameters for the Test Structure

[72], [76][118]……… 75Table 15:Average Cu/O Atomic % for different samples from EDS ………… 84

薑黃素對胰液所誘導肺損傷之保護效用

為了解決Saffron 46 ig 的問題,作者陳冠豪 這樣論述:

中文摘要 近日在全地引起的新興疾病諸如中東呼吸症候群(middle east respiratory syndrome, MERS)、急性呼吸道症候群(severe acute respiratory syndrome, SARS)以及伊波拉病毒、炭疽桿菌和退伍軍人桿菌等引起的高死亡率,均與肺部的發炎、肺部的水腫相關。其發病機轉除了與微生物感染有關外,肺部的嚴重發炎反應也扮演極重要的角色。肺部的炎症可因發炎細胞滯留在肺內,引起肺內氧化壓力的上升、肺循環壓力上升及肺微血管通透性的增加。此外血球滯留在肺內引起的肺組織缺血或再灌流,也有一定的關係。腸道的壞死、胰臟的發炎也會引起全身性的發炎反

應,進而引起肺臟的血流動力學的改變,肺微血管的通透性增加,緊接著引發肺水腫的現象。在初步研究中發現,當肺組織在缺血再灌流的環境下,肺內的積水上升(p &;lt; 0.01)、肺組織灌洗液中蛋白質(PCBAL)含量上升(p &;lt; 0.001)及肺微血管通透性上升(p &;lt; 0.05)。使用了水溶性的氧自由基吞噬劑(dimethylthiourea)後損傷的參數均明顯改善(PCBAL, p &;lt; 0.01; 肺重/體重比(LW/BW),p &;lt; 0.05),而大分子量的自由基吞噬劑superoxide dismutase以及catalase就未呈現有保護作用(p &;gt;

0.05),此可能與這兩者的蛋白質分子量太大無法進入細胞內有關。在另一組實驗中,我們證實當胰臟在缺血再灌流引發之胰臟發炎後,呼吸道的反應性會上升(p &;lt; 0.001)。此反應性的上升應該與發炎反應、肺內白血球的上升以及腫瘤壞死因子、羥自由基、氮化壓力上升有關。使用抗氧化劑薑黃素後,這些反應均明顯減少。由於胰臟缺血再灌流後血中澱粉酶、脂肪酶及蛋白酶的上升間接證明是因胰液外滲到血液中(p &;lt; 0.01),進而進入肺內引發肺部的發炎甚至水腫。因此在進一步的研究中,我們建立了以胰液直接噴灑至實驗大鼠呼吸道的實驗模式。在實驗中證實胰液會引發阻塞性及限制性肺部功能變化,此與肺部發炎性反應

有關。此外,引發肺微血管通透性病變,血液中白血球數量上升、紅血球數量降低。此外,血紅素、血球容積比、平均紅血球容積、平均紅血球血紅素重量、平均紅血球血紅素濃度等均上升,並且使血小板數值下降,進而造成瀰漫性血管凝血現象。在血清與肺組織灌洗液中均發現乳酸脫氫酶(lactate dehydrogenase, LDH)上升,顯示細胞損傷嚴重。在使用全套肺功能相關生理試驗(pulmonary function test, PFT)發現最大自發性換氣量、中間潮氣呼氣流量、阻力指數、肺活量、呼吸功、最大呼氣流速、最大中段吐氣流量及用力吐氣時間在50%的氣體流量均下降,而肺總量、肺餘容積和肺順應性(chord

compliance)則是上升,顯示出肺功能因此受到影響。使用薑黃素後對於實驗大鼠的支氣管灌洗液(bronchoalveolar lavage fluid, BALF)中的蛋白質、血清中的氮化壓力、氧化壓力、乳酸脫氫酶以及肺功能參數,均顯示具有明顯的保護效用。透過本研究證實薑黃素具備強力的抗氧化能力,可減少氧化壓力及氮化壓力,以致無論在缺血再灌流或是胰液引發的肺損傷及肺功能改變,均能產生明顯的改善效果。此外本研究也建立了一個以霧化胰液至肺內引發肺損傷的實驗模式,對於胰臟發炎及肺部病變提供了一個很好的實驗模式。

想知道Saffron 46 ig更多一定要看下面主題

Saffron 46 ig的網路口碑排行榜

-

-

#2.【炸香銷魂1】Saffron 46番紅花四十六勾魂印度香料

其實,在這個香料王國中,最不思議的美味,正是街頭巷尾常見的油炸小吃。 位於台北微風南山百貨的「番紅花四十六」(Saffron 46),旅居台灣二十多年的 ... 於 tw.yahoo.com -

#3.微風南山頂級印度菜– SAFFRON 46 番紅花46 - Toby is Here

今天又到了信義區來欣賞高空景觀餐廳,繼之前在Morton吃了以後,又一次造訪了高空餐廳。SAFFRON番紅花46是印度菜餐廳,說到印度菜,那肯定是重口味的。 於 tobywc.com -

#4.<Saffron 46>不一樣的印度料理體驗 - 放縱人生 Fun Life - 痞客邦

Saffron 46> 相較路上隨處可見的日式、韓式、義式、美式餐廳,印度料理一直在台灣的美食圈算是比較小眾的分類這次選擇的Saffron 46,不僅僅因為是 ... 於 wendyvivieng.pixnet.net -

#5.ScubaGolfer's blog - 台北外食‧ 2020 - Udn 部落格

印度:Saffron 46. 在號稱「台魂法菜」領軍下,創意融合西式小餐廳 ... 好此道者有興趣歡迎看看Instagram 就是. 揮別動亂不安的2020,祝大家今年平安 ... 於 blog.udn.com -

#6.Saffron 46餐廳- ,TPETaipei City - OpenTable

以珍饈香料「番紅花」為名的SAFFRON 46 番紅花四十六,位於信義區微風南山46樓,透過傳統料理手法結合現代視覺的印度菜餚,呈獻出其文化多變之色彩與正宗且纖細的 ... 於 www.opentable.com.tw -

#7.2023跨年餐廳TOP8推薦!高樓層餐廳享受大餐、近距離的觀賞 ...

其中微風南山-MiraWan、新葡苑四十六、和牛47、Smith&Wollensky、SAFFRON46;微風信義-MORTON'S、饗饗、Sea to sky、麻辣45等主題餐廳,12/31(六)當晚 ... 於 www.look-in.com.tw -

#8.SAFFRON 46 Breeze - 微風廣場

SAFFRON 46. 以最珍貴的香料番紅花為名,將印度千變萬化的香料與不同地區的道地風味結合,番紅花一直是台北印度料理餐廳中最響亮的名字。2018 底這朵深受饕客喜愛的番 ... 於 www.breezecenter.com -

#9.Lemony Lentil Soup Recipe | Gimme Some Oven

Simmer. Stir in the vegetable stock, lentils, corn, cumin, curry powder, cayenne and saffron (if using) until combined. Cover and cook (or ... 於 www.gimmesomeoven.com -

#10.Marie 林瑪莉on Instagram: “有美景又有美食的Saffron 46 印度 ...

1 Likes, 1 Comments - Marie 林瑪莉(@lightmarielin) on Instagram: “有美景又有美食的Saffron 46 印度料理真的好好吃 好值得一直回訪的店很適合聚餐和約會的餐廳 於 www.instagram.com -

#11.【購物】在家也能享受米其林必比登Saffron 番紅花_印度咖哩

[代購團購]台北知名Saffron 番紅花「療癒吮指_印度咖哩_冷凍即食包」.番紅花咖哩包在手, ... 番紅花特製雞肉咖哩Saffron 46 Curry $ 300 於 www.backpackers.com.tw -

#12.微風南山美食餐廳推薦,全樓層介紹,信義區IG打卡新地標

以及微風南山必吃的甜點 微風南山美食餐廳推薦,全樓層介紹,信義區IG打卡新 ... 南山營業樓層包括地下樓B1,B2,1樓至7樓,以及46,47,48樓的高樓層, ... 於 maggielife.tw -

#13.Rohan josh/lamb instant packet from Saffron 46. - Instagram

40 Likes, 1 Comments - @foodmakesmehappy on Instagram: “Rohan josh/lamb instant packet from Saffron 46. 番紅花/Saffron 46印度咖哩冷凍即食包- 喀什米爾羊肉 ... 於 www.instagram.com -

#14.HUHGRY 都會男子|台北美食on Instagram: “.: Saffron 46

1 Likes, 0 Comments - HUHGRY 都會男子|台北美食(@huhgry) on Instagram: “.: Saffron 46 :. . FOOD POV SERVICE RATE ... 於 www.instagram.com -

#15.47樓餐廳. 高空餐廳推薦|微風南山Saffron 46,全台最高印度 ...

全台最高印度料理番紅花四十六Saffron 46樓台北高空景觀餐廳,101近在 ... 某天看到IG有人分享這家餐廳~ 美好的餐廳氛圍還能夠近離距欣賞101 深深吸引 ... 於 nvp.kwadranspabianice.pl -

#16.頂級印度菜百元起吃得到!微風南山Saffron 46午間優惠套餐

由知名印度餐廳番紅花開設、位在微風南山46樓的「Saffron 46」自開幕後好評不斷,不僅能品嘗印台雙主廚的美味料理,華人雞尾酒教父Aki領軍的調酒 ... 於 www.mingweekly.com -

#17.Saffron 46

以珍饈香料「番紅花」為名的SAFFRON 46 番紅花四十六,位於信義區微風南山46樓,透過 ... di Ewan 1k Posts - See Instagram photos and videos taken at 'Saffron46' ... 於 gbfh6.rawek.pl -

#18.微風南山Saffron 46 - 好久沒碰上全四星評價的餐廳

主要是Saffron 46的調酒還挺合味口,原本只是想試喝一杯,. 草本調性的調酒深得我心,顯少午餐時段喝超過一杯的我竟然追加第二杯,. 輕而易舉達成 ... 於 cindylo326.pixnet.net -

#19.【微風南山】SAFFRON 46 番紅花四十六/揉合傳統與現代的 ...

【微風南山】SAFFRON 46 番紅花四十六/揉合傳統與現代的印度料理. SAFFRON 46 番紅花四十六,位在信義區微風南山46樓面向臺北101那一側要從 ... 於 dianamaster.com -

#20.疫情好轉後,不論是小酌約會、談生意看景,這是最適合的地點 ...

580 Likes, 39 Comments - BECKY 傅靖瑜(@miss.becky.lawyer) on Instagram: “《Saffron Bar 》謝謝Saffron 46邀請,疫情好轉後,不論是小酌約會、談生意看景, ... 於 www.instagram.com -

#21.網路上關於SAFFRON 46-在PTT/MOBILE01/Dcard上的升學 ...

2022SAFFRON 46討論資訊,在PTT/MOBILE01/Dcard上的升學考試資訊整理,找SAFFRON 46在Instagram影片與照片(Facebook/Youtube)熱門討論內容就來大學國高中學習補習資源 ... 於 student.gotokeyword.com -

#22.嘉義瑞里紫藤花季精選「解憂咖啡店」TOP 6 -

擁有最美紫衣裳的紫藤花美照即將洗版網路,繼櫻花和黃花風鈴木之後,你的FB、IG準備再刷一片粉紫!三月嘉義瑞里紫色山城浪漫如花語「沈醉在戀愛裡」, ... 於 tpnews.org -

#23.Saffron 46 - HUHGRY 都會男子|台北美食on Instagram

1 Likes, 0 Comments - HUHGRY 都會男子|台北美食(@huhgry) on Instagram: “.: Saffron 46 :. . FOOD POV SERVICE RATE ... 於 www.instagram.com -

#24.saffron 46 - 【台北信義區】與101對望,時尚異國浪漫印度料理

位於台北信義區101對面的saffron 46,微風南山46樓的高空景觀餐廳,主推以道地印度香料製作而成的美食,並用珍饈香料番 ... View more on Instagram. 於 www.popdaily.com.tw -

#25.2023台北8間情人節熱門首選「約會景觀餐廳」飽覽101浪漫 ...

圖/[email protected]. /. 圖/[email protected] ... 信義區微風南山46樓的「Saffron 46 番紅花四十六」,也是米其林必比登曾經推薦的一家美食餐廳! 於 doddlemeal.com -

#26.Saffron46 番紅花四十六| 微風南山北市最高的印度料理

Saffron46 番紅花印度印度美饌,在信義區的46樓層插旗,透過傳統料理的手法,結合現代視覺的印度料理,來呈現菜色多變之色彩與正宗纖細的風味。 於 www.travelwithjason.com.tw -

#27.Karabük GoTürkiye Destinations

Karabük's touristic district Safranbolu received its name from the saffron flower, which is famous for its colour, smell and economic value. Get More ... 於 karabuk.goturkiye.com -

#28.< 外食日記>SAFFRON 46 番紅花四十六 - Instagram

567 Likes, 18 Comments - Aimee Liu (@aimee_liuu) on Instagram: “< 外食日記>SAFFRON 46 番紅花四十六 真的不知道要怎麼說,鼎鼎大名的印度 ... 於 www.instagram.com -

#29.Saffron46 - Inspot IG熱搜

超夯打卡景點Saffron46,網美最愛打卡景點,地址在110台灣台北市信義區松智路17號46F,趕緊來踩點打卡! 於 inspot.fun -

#30.正妹美食地圖|男人夢想職業護理師—依依x Saffron 46

還有一個女小編很佩服的夢想,就是環遊世界,到各國去當醫療志工,依依不只美,心地還很善良,娶老婆就是要娶這種的! 追蹤數2w. 依依IG: https:// ... 於 a0929755755.pixnet.net -

#31.信義區Saffron46 - TikTok

來自我餓「 IG 分享更多美食」 (@52_foodie) 的TikTok 影片:「信義區 Saffron46 」。 原聲- 52_foodie 「 IG 分享更多美食」 - 我餓「 IG 分享更多 ... 於 www.tiktok.com -

#32.近距離感受震撼信義區13家可以欣賞台北101煙火高樓餐廳

△Saffron 46平常用餐享受101就在眼前的奢華夜景。(圖/Saffron 46提供). Saffron 46 ... 更多吃喝玩樂大小事,快追隨旅遊雲官方Instagram. 於 travel.ettoday.net -

#33.Saffron 46 印度料理|台北微風南山高樓層餐廳,視覺味覺都享受

「不過就是印度料理嘛」,以前我也這麼想,實際到Saffron 46吃了一輪,才發現一點也不簡單! ... 我的IG有更多美食、品酒情報,快追蹤起來! 於 natasha-traveler.tw -

#34.誰說高樓景觀餐廳一定貴?微風南山Saffron 46推出「千元有找 ...

微風南山Saffron 46推出「千元有找」套餐,享用道地印度料理還能俯瞰台北市美景! 招牌慢燉羊膝真的是入口即化啊! By Ray ... 於 www.harpersbazaar.com -

#35.saffron46特製雞肉咖哩Instagram Posts - Picuki.com

#saffron46特製雞肉咖哩 Instagram Posts. SAFFRON 46 番紅花四十六,曾獲得米其林必比登推薦!在信義微風南山46樓,101就在窗外,是間道地好吃的印度餐廳,有咖哩、烤 ... 於 www.picuki.com -

#36.saffron 46 grand opening - Instagram

116 Likes, 9 Comments - Saffron 46 (@saffron46.taipei) on Instagram: “SAFFRON 46 GRAND OPENING Let's celebrate! Our restaurant has opened on the 46th floor ... 於 www.instagram.com -

#37.番紅花46 / Saffron 46,微風南山現代印度料理,坐享臺北101 ...

想要看著臺北101的景觀用餐嗎?信義區微風南山46樓,曾獲得米其林必比登推薦的番紅花46 / Saffron 46,以法式餐廳的氣質,端出現代印度料理的精緻美味 ... 於 www.daisyyohoho.com -

#38.跨年看101 煙火免人擠人最後卡位機會!信義區高樓層餐廳總整理

價格:以桌計價,32000 元+10% 起/ 桌,含桌次對應人數套餐、香檳無限暢飲。 【微風南山SAFFRON 46】. 價格:跨年場(座位區)20:45~02:00. 靠 ... 於 www.upmedia.mg -

#39.台北市·微風南山Saffron46 印度料理 威士忌 ... - Instagram

171 Likes, 4 Comments - Stanley (@stanley_0905) on Instagram: “台北市·微風南山Saffron46✨ 印度料理 威士忌 view Indian cuisine ... 於 www.instagram.com -

#40.Saffron 46 網友評價、菜單| 台北信義區咖哩- 愛食記

Saffron 46 是位於台北信義區的網友推薦餐廳,地址: 臺北市信義區松智路17號46F,訂位電話: 0227225151, ... Saffron 46番紅花四十六印度料理,微風南山46樓,約會推薦! 於 ifoodie.tw -

#41.Our Menu - Saffron Coffee

A stack of Saffron Coffee gingerbread-spiced pancakes with banana, vanilla ice-cream, ... Big Breakfast - 51 ... Chicken Pesto Panini - 46. 於 saffroncoffee.com -

#42.看台北101煙火最佳視角!信義區8間「高空餐廳」嘗跨年套餐

Ce La Vi · SMITH&WOLLENSKY · SAFFRON 46 · 和牛47 · SEA TO SKY · MORTON'S莫爾頓牛排館 · 掌門精釀啤酒. 於 playing.ltn.com.tw -

#43.Menus | Quality Bistro in New York, NY

Saffron Aioli, Potato Gaufrette. $24. Local Fluke Crudo ... Big Glory Bay King Salmon. Truffled Leeks, Sauce Perrier-Jouët. $46. Dover Sole. á la Meuniére. 於 www.qualitybistro.com -

#44.生日餐之一at Saffron46 第一次嘗試印度料理從前菜 ... - Instagram

40 Likes, 1 Comments - Joy🕊️ (@joyhsu.17) on Instagram: “:: 生日餐之一at Saffron46 第一次嘗試印度料理從前菜、主食到甜點都令人滿意最驚艷的是酸奶多重奏直接 ... 於 www.instagram.com -

#45.微風南山美食。SAFFRON 46 番紅花四十六︱俯視大台北高空 ...

曾在【微風南山】開幕之初造訪過一次的《SAFFRON 46》,是天母名店番紅花開設的分店品牌, ... 美食IG:wiselyfood/旅遊IG:wiselyview. Saffron 46 ... 於 www.wiselyview.cc -

#46.台北微風南山奢華高空餐廳: Saffron46 番紅花四十六 - 焦糖熱一點

第一天,先生預約了46層樓的「Saffron46 印度料理」,簡單度過結婚周年紀念日,由於微風南山用餐的氛圍相當浪漫,和先生邊吃印度料理的同時,馬上預約了 ... 於 www.biteamap.com -

#47.全台最高 印度料理【番紅花Saffron 46 樓高空景觀餐廳】道地 ...

番紅花四十六位在微風南山信義區微風南山艾妥列星空塔46樓,Saffron 46 提供道地北印度風味料理,除美味佳餚外,身處在46樓景觀餐廳,不僅可以俯視大台北 ... 於 f6616tw.pixnet.net -

#48.千元浪漫約會餐廳近距離吃正餐看101美景|Saffron46印度精緻 ...

台北2018米其林指南|台北高樓景觀餐廳Saffron 46. ... 追蹤我的平常生活 https://www.instagram.com/wei102299/ 追蹤我的粉絲團. Wei撲克人妻日常 ... 於 wei102299.pixnet.net -

#49.[台北美食] 微風南山【番紅花四十六Saffron46】高樓層景觀餐廳 ...

【番紅花四十六 Saffron 46】. 將會打破你對印度菜的傳統認知,. 正宗又道地的菜色,印度料理絕不只有咖哩和烤餅,. 再搭上精心的烹調和擺盤,讓餐點的香料風味特色更 ... 於 eggface45.pixnet.net -

#50.[食記] 微風南山餐廳。台北「陳興發興記菜館」開幕囉~推薦必 ...

《追蹤西西IG》 ... [新開店] 微風南山。46F星空塔Sky Tower搶先看! The Ukai Taipei。SHIN PU YUAN 新葡苑四十六。SAFFRON 46 《西西的旅行部落格》. 於 www.sisicooking.com -

#51.高樓層景觀餐廳-Saffron 46❤️ - Instagram

154 Likes, 13 Comments - Ashley Hui Lin (@huissweetsnote99) on Instagram: “高樓層景觀餐廳-Saffron 46❤️ 微風南山46樓時尚印度料理 誠摯 ... 於 www.instagram.com -

#52.Saffron 46 (@saffron46.taipei) • Instagram photos and videos

Modern Indian cuisine, urban dining experience, and craft cocktails overlooking the Taipei skyline. Reach us at 02-2722-5151. · 114 posts · 4,068 followers · 20 ... 於 www.instagram.com -

#53.【台北美食】Saffron 46番紅花四十六|超高樓層景觀餐廳

以珍饈香料「番紅花」為名的 SAFFRON 46 番紅花四十六 ,透過傳統料理手法結合現代視覺的印度菜餚,呈獻出其文化多變之色彩與正宗且纖細的風味,Saffron46 bar 大氣挑 ... 於 pickyeaterr.com -

#54.[Taipei] SAFFRON 46 番紅花四十六 - Zoecolatte

SAFFRON 46 的開幕確實令人興奮,由番紅花印度美饌Saffron Fine Indian cuisine 和Indulge Bistro 合作。 - 若是不常吃印度菜的人仍然值得前往嘗試,若是一個印度菜 ... 於 zoecolatte.net -

#55.Saffron 46 | 立即訂位!inline 線上訂位預約

以珍饈香料「番紅花」為名的SAFFRON 46 番紅花四十六,位於信義區微風南山46樓,透過傳統料理手法結合現代視覺的印度菜餚,呈獻出其文化多變之色彩與正宗且纖細的 ... 於 inline.app -

#56.Absolutely Fabulous - Wikipedia

Absolutely Fabulous is a British television sitcom based on the French and Saunders sketch, ... Edina is reliant upon the support of her daughter Saffron, a student and ... 於 en.wikipedia.org -

#57.[食記] 台北信義Saffron 46 高樓景觀餐廳享受精緻印度料理和

餐廳名稱:Saffron 46 消費時間:2022年/2月110台北市信義區松智路17號46F 人均: 2000 11:30am~11pm. ... instagram: @superdhuang. 於 ptt.reviews -

#58.【微風南山美食】SAFFRON 46 番紅花四十六,台北101就在眼前

SAFFRON 46 番紅花四十六,位於微風南山的46樓,神秘的46樓中共有The Ukai Taipei、SHIN PU YUAN 新葡苑四十六、SAFFRON 46 其中以SAFFRON. 於 love708694.pixnet.net -

#59.Saffron46 - 鏡週刊Mirror Media

摩登印度餐酒搭耳畔響起英倫樂團Coldplay樂曲. 「Saffron 46」是台北天母地區的餐廳「番紅花」在獲得米其林餐盤及必比登推薦後,前進信義區的首家分店。 於 www.mirrormedia.mg -

#60.See this Instagram photo by @saffronbarker • 20.6k likes

See this Instagram photo by @saffronbarker • 20.6k likes Saffron Barker, Youtubers, ... Instagram post by Saffronbarker • Feb 16, 2017 at 5:46pm UTC ... 於 www.pinterest.com -

#61.Dante NYC | Italian Small Plates & Cocktails in New York City

... manchego, Parmigiano Reggiano, served with lightly salted bread balls 46 ... olmeca altos. orange dry curacao. fluffy clementine. lime. saffron. 於 www.dante-nyc.com -

#62.Jambalaya - Cafe Delites

Saffron is the main spice component in Paella, and Paella is milder than Jambalaya in ... Calories: 576kcal | Carbohydrates: 46g | Protein: 43g | Fat: 22g ... 於 cafedelites.com -

#63.絕美信義區夜景餐廳|全台最高印度料理|Saffron 番紅花46

在Instagram 查看這則貼文 ... 微風南山的#Saffron46 兼具了南北印度菜色番紅花老闆特別請了印度廚師團隊把正宗印度料理帶進優雅的夜景餐廳用精緻的 ... 於 cheapbutpractical.com -

#64.微風南山高空奢美餐廳「Saffron 46」套餐千元有找!道地印度 ...

PHOTO CREDIT: Saffron 46 全台最高景觀印度料理餐廳的「 Saffron 46」由印度籍主廚Sudhir領. 於 buy.line.me -

#65.台北高樓景觀餐廳|非凡跨年夜!!享受美食坐看101夜景 - GOMAJI

Saffron46 圖片來源自IG:fooddict.tw. 46樓的高樓景觀餐廳將101與台北市容盡收眼底,讓人沉醉其中的高級奢華裝潢,與正港印度人師傅烹調出的精緻道地 ... 於 www.gomaji.com -

#66.【台北高空餐廳】Saffron 46番紅花四十六印度料理 - 窩客島

趁著Jeffy三月生日,我們決定再一次收集台北的高空餐廳啦!之前花了不少時間找尋101附近的高空餐廳,發現這間位於微風南山的「Saffron46番紅花四十 ... 於 www.walkerland.com.tw -

#67.Saffron 46 on Instagram: “What a better way to start the Lunar ...

322 Likes, 1 Comments - Saffron 46 (@saffron46.taipei) on Instagram: “What a better way to start the Lunar New Year than our exciting dishes ... 於 www.instagram.com -

#68.Spanish Paella | RecipeTin Eats

This famous saffron infused rice dish is a traditional Spanish recipe that comes ... Pinterest and Instagram for all of the latest updates. 於 www.recipetineats.com -

#69.【台北市信義區美食】Saffron 46 - 網友評價、菜單、推薦餐點

Saffron 46 是一間位於台北市信義區的現代印度餐廳,總共有1164位網友評價過此 ... 某天看到IG有人分享這家餐廳~ 美好的餐廳氛圍還能夠近離距欣賞101 深深吸引了我!! 於 ihungrybear.com -

#70.台北|SAFFRON 46番紅花四十六,全台最高印度佳餚 - oopsWu

台北|SAFFRON 46番紅花四十六,全台最高印度佳餚,欣賞台北101的絕佳視野。 · 分享此文: · 請按讚: · 相關 · FACEBOOK · IG. 於 oopswu.com -

#71.[食記] 台北信義Saffron 46 高樓景觀餐廳享受精緻印度料理和

餐廳名稱:Saffron 46 消費時間:2022年/2月110台北市信義區松智路17號46F 人均: ... https://blog.superd.org/podcasts instagram: @superdhuang ... 於 moptt.tw -

#72.Find a class - Little Kickers

Find a football class to match your child's age and in your local area. There are no specific start and end dates, just sign up online and join in! 於 www.littlekickers.co.uk -

#73.SAFFRON 46, Xinyi District - Menu, Prix, Restaurant Avis ...

Réserver une table Saffron 46, Xinyi District sur Tripadvisor : consultez 48 ... No.17 Songzhi Road 46F Nanshan Breeze, Xinyi District, Taipei 106 Taïwan ... 於 www.tripadvisor.fr -

#74.Saffron 46 Taipei 》這家台北印度料理餐廳除了美食也有高水準 ...

♛ This is a promotion article, but state the true and sincere review. ♛ About Me | Front Page. ♛ Facebook | IG | Youtube ... 於 globalfoodelicious.com -

#75.Saffron46 | Taipei - Facebook

7.9K likes. . 8.7K followers. @saffron46. . Follow. . Posts · About. Photos. Videos · Mentions. Photos of Saffron46. 91 photos. Saffron46's Photos. 於 www.facebook.com -

#76.聖誕餐, 台北印度料理餐廳Saffron 46, girls night out ... - YouTube

vlogmas: 聖誕餐, 台北印度料理餐廳 Saffron 46, girls night out, secret santa 交換禮物, 姐妹生日小驚喜, christmas 2021 . 於 www.youtube.com -

#77.Saffron 46: Delicate Indian Cuisine - CommonWealth Magazine

My Dilli Pani Puri soon arrive and I'm warned that the Spice Water is very spicy and it's recommended I only pour a little in before eating* ... 於 english.cw.com.tw -

#78.Currys Store Finder

All TVs · 75'' or more TVs · 65'' - 74'' TVs · 55" - 64" TVs · 46'' - 54'' TVs · 39'' - 45'' TVs ... Facebook · Twitter · Pinterest · Instagram · YouTube. 於 www.currys.co.uk -

#79.15 fine dining restaurants in Gloucestershire, Cotswolds ...

Instagram · The Wild Rabbit is a stylish gastropub located in the Cotswold village of Kingham. Offering modern British menus created using ... 於 www.soglos.com -

#80.【微風南山美食】台北新熱點!微風南山必吃餐廳、甜點及飲料

圖片來源: shin.prince @ Instagram. 微風南山於2019年1月10日開幕,位於 ... 新葡苑四十六THE UKAI TAIPEI SAFFRON 46 和牛47 Smith & Wollensky ... 於 bravel.yas.com.hk -

#81.Saffron 46 - MENU 美食誌

Saffron46 分有用餐區及Saffron46 bar 是全亞洲50大酒吧 調酒非常有水準謝謝@伊伊提供美照 . 2022-12-25 ... 印度料理 Instagram: wenlingwoo. 2020-12-08. 於 menutaiwan.com -

#82.炎炎夏日讓人開胃舒心的SAFFRON 46 日前,酒探兩支酒款

26 Likes, 2 Comments - Dunstan Vintner Taiwan (@dunstanvintner) on Instagram: “⠀ ╸炎炎夏日讓人開胃舒心的SAFFRON 46╺ ⠀ 日前,酒探兩支酒款-McHenry…” 於 www.instagram.com -

#83.TK SEAFOOD & STEAK、Saffron 46、天香樓獵食指南!深秋 ...

位於微風南山46樓的Saffron 46突破大部分人對印度料理的認知侷限,邀請曾師承名廚Alain Passard ... 印度料理的纖細展現Saffron 46 ... 圖片來源:diptyque IG). 於 www.wowlavie.com -

#84.微風南山美食。SAFFRON 46 番紅花四十六 - 嘿!部落!

曾在【微風南山】開幕之初造訪過一次的《SAFFRON 46》,是天母名店番紅花開設的分店品牌, ... 美食IG:wiselyfood/旅遊IG:wiselyview. Saffron 46 ... 於 ha-blog.tw -

#85.全台最高印度料理番紅花四十六Saffron 46樓台北高空景觀餐廳

兒童:餐廳無提供兒童餐,若有需要兒童椅及兒童餐具請提前告知。Saffron46菜單,餐點種類超多,眼花撩亂,選擇障礙的會很難選,中午推出saffron 46商業 ... 於 upssmile.com -

#86.[亂吃美食] 台北信義Smith & Wollensky 高空景觀牛排餐廳(微風 ...

另外46-48層為星空塔Sky Tower,目前已有7家的高樓景觀餐廳分別是新葡苑四十六、Saffron on 46、The Ukai Taipei、和牛47、Smith ... 於 yuchulien.pixnet.net -

#87.台北市信義區美食:: Saffron 46 印度番紅花料理微風南山46樓 ...

就像標題說的Saffron 46 是天母非常道地的印度餐廳番紅花印度美饌全新品牌沒有兩把刷子怎麼可能在微風南山開店呢其實我沒去過印度我也不知道跟當地的 ... 於 cndjourney.pixnet.net -

#88.Find Us - Saffron Culture

Saffron Culture 46 Plaistow Lane Sundridge Park, Bromley ... Instagram: instagram.com/Saffron_Culture. Twitter: twitter.com/SaffronCulture. 於 saffronculture.co.uk -

#89.[食記] 台北-Saffron 46 - 三高Sir的美食足跡

mail button icon · facebook button icon · instagram button icon. 照片記錄:兩人3.5k。 天母番紅花的微風南山版,午後無休可作為下午茶輕鬆吃, ... 於 thudadai.pixnet.net -

#90.2 Cornwall gastropubs named among best in UK for 2023

The full list of the 50 gastropubs can be seen on the Big 7 Travel website here. ... and for summer there's fresh monkfish with saffron.". 於 www.falmouthpacket.co.uk -

#91.Saffron 46 (高級インド料理) | 台湾で食べまくり peko - FC2

微風南山にオープンした高級インド料理のレストラン。 天母にある人気インド料理のお店の支店です。 World Cocktail Championshipにて3度も一位に輝い ... 於 tabemakuripeko.blog.fc2.com -

#92.微風南山46樓美食【Saffron 46番紅花四十六】101美景超無敵 ...

某天看到IG有人分享這家餐廳~ 美好的餐廳氛圍還能夠近離距欣賞101 深深吸引了我!! 立即上網查了一下他的評價及價位~ 並不是那麼的高不可攀立馬傳給 ... 於 beautychu060.pixnet.net -

#93.Saffron 46 番紅花四十六-與台北101共享精緻印度料理 - kara in-

Mumbai 一樣好吃的印度咖喱,聽說Saffron46很好吃所以很期待在生日時吃到! 餐廳內的裝潢很有質感又很平易近人,還加了一些圖騰讓整體看起來十分「異國」 ... 於 kararalolo.tumblr.com -

#94.全台最高「印度料理」在台北!必嘗三角形餃子、炸小圓餅

全台最高印度料理!《食尚玩家》推薦台北這家「Saffron 46」,在這個坐擁101高空美景的景觀餐廳,不僅能嘗到與Fine Dining結合的道地印度料理, ... 於 supertaste.tvbs.com.tw -

#95.saffron 46 米其林的推薦與評價 - 最新趨勢觀測站

關於saffron 46 米其林在[食記]台北/信義區微風南山Saffron 46 印度菜- 看板Food 的評價; 關於saffron 46 米其林在Saffron46 - 在家也能享受米其林必比登推薦料理Saffron ... 於 news.mediatagtw.com -

#96.saffron46.taipei 番紅花46印度料理在天母知名的 ... - Instagram

277 Likes, 14 Comments - 克萊兒食尚生活(張立妍) (@clairechang) on Instagram: “@saffron46.taipei 番紅花46印度料理在天母知名的米其林推薦印度餐廳「番紅花印度美 ... 於 www.instagram.com -

#97.微風南山Saffron 46,全台最高印度料理,那一夜在46樓星空塔 ...

追蹤劈腿女孩Yaya的IG. SAFFRON 46 番紅花四十六. 電話: 02-27225151. 地址:台北市信義區松智路17號(微風南山46樓). 來到位於微風南山星空塔46 ... 於 yaya.tw -

#98.CONTACT - SAFFRON 46 番紅花四十六

SAFFRON 46 番紅花四十六台北市信義區松智路17號微風南山46樓. Breeze Nan Shan 46F, No.17 SongZhi Road, Xinyi District, Taipei. Telephone ... FB · Instagram. 於 www.saffron46.com